Coil Control's Laser Loop Control |

|

Unreliable loop controls cost you thousands of dollars in lost production, wasted material and tooling damage.

You can regain control of your coil processing equipment.

Coil Control's Laser Loop Control System is designed to measure distance based on the "time-of-flight" principle. Each transmitted photon travels at a constant rate to the target and back to the sensor. The measured time is directly proportional to the distance traveled. |

Works in Any Environment |

|

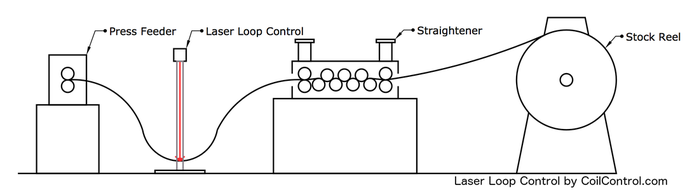

Coil Control’s new Laser Material Loop Control provides non-contact control of continuous material payout for the metal stamping industry. The laser loop control has many advantages over other loop controls:

|

Easy Setup |

|

Set up of the laser material control is fast, simple and does not require any programming. A large 4-digit alphanumeric display with simple push buttons are used to set up device parameters.

The unit can provide a 0-10VDC or 4-20mA analog signal to control a variable speed drive. The analog signal can be scaled to operate with material loop sizes from 24" to 240" deep. A tight loop relay output interlock is also provided. |

Superior Reliability |

|

Rock solid. Tested in industrial workplaces.

The industrial design of the Coil Control's Laser Material Loop Control utilizes SoC (system-on-chip) design for superior reliability in the most brutal of operating environments found in the coil metal processing industry. |

| Laser Loop Control Product Brochure | |

| File Size: | 288 kb |

| File Type: | |